Kent Renewable Energy Biomass Plant

We opened our combined heat and power plant in September 2018, generating just over 27MW of green electricity, which is enough to supply 50,000 homes and save over 100,000 tons of CO2 every year. It’s difficult to visualise how much this is, however the saving is equal to over 1 million plane flights to Paris or nearly 28 million miles driven by an average car – the same as driving around the world nearly 1,135 times. Around 15% – 20% of the clean, green energy we generate is supplied directly to the tenants of Discovery Park, who also benefit from heat generated by the steam from our plant.

Generating

of green electricity

Supplying

homes with energy

Saving over

tons of CO2 a year

Powering Discovery Park

Our renewable biomass combined heat and power plant is providing renewable heat and electricity to Discovery Park, one of Europe’s leading Science and Technology parks, near Sandwich in Kent. All the businesses and activities that have made their home at Discovery Park are able to power themselves and keep warm with renewable energy on a daily basis. All the energy we generate which they don’t use is then sent to the local electricity grid to power homes across the region.

Sustainability

We want to ensure that not only are we producing clean, green heat and power but that we are also developing sustainable operating procedures for our power plant and throughout our supply chains as we strive to remain a flagship project across the region and beyond. To achieve this we are ensuring we promote active carbon balancing across the region by promoting the use of coppiced woodland techniques through our suppliers woodland management plans. These plans also enable older trees to be replaced with more newly planted younger trees which remove more CO2 from the atmosphere, once again creating active carbon balancing.

All our wood suppliers utilise respectful management practices which promote biodiversity and so are helping the region to reverse the catastrophic declines in key bird and butterfly species which has taken place over recent years. As all our wood comes from sustainably managed woodland, it is accredited by the Forest Stewardship Council who also ensure the sustainability of the processing and supply chains as well.

Reinvigorating the woodlands of south east England

Whilst the South East of England is one of the most densely populated parts of the country, surprisingly it is also one of the most densely wooded. There are 790,000 acres of woodland in the South East and London area, but only 46% is currently managed. The local paper and coppice industries used to provide markets for these woodlands but the decline in these industries has led to over 430,000 of the 790,000 acres of regional woodland becoming unmanaged.

This leaves about 175,000 hectares of useable woodland for which there is no long-term management plan or economic use. Unmanaged woodlands represent a huge opportunity in terms of carbon balances, biodiversity management, employment opportunities and productive potential.

By providing a significant local market for low-grade wood, our power plant is re-vitalising local forestry. We are achieving this by providing a secure alternative market for an historical industry in the region, redeveloping the sustainable markets woodland owners need to have the confidence to begin managing their woodlands once more.

“It is widely agreed that local bioenergy offers the single biggest opportunity for bringing woodland back into active management, making the South East’s woodlands as environmentally diverse, sustainable and productive as possible”

This renewed industry confidence also enables the growth of local employment opportunities in forestry, ensuring these tradition skills are not lost. As more and more woodlands are brought back into active management they act as the catalyst for further areas to develop active management plans. Ensuring well managed forests is great for everyone as they provide clean air and water, flood management, homes for wildlife, beautiful scenery, places for recreation and more than 5,000 products we all use every day.

Construction programme

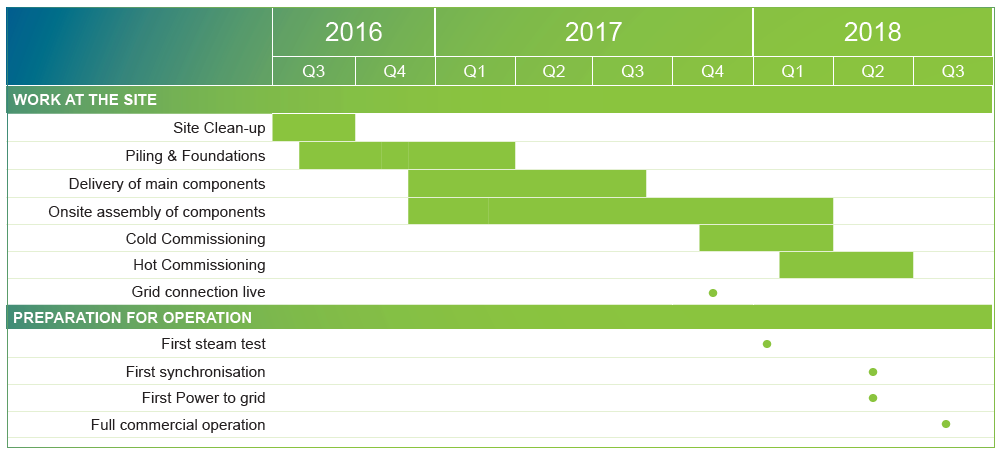

We first began constructing our biomass CHP plant in the summer of 2016. This included the wood reception and handling facilities where we receive our wood fuel as both logs and wood chips, the wood storage barn and the fuel crane that mixes the wood and places it on the conveyor ready to go to the boiler.

The boiler itself was assembled during the summer of 2017, with the turbine and generator lifted in to place and aligned. On 18th December 2017, the site was made live for the first time by importing power from the grid through the main transformer. This allowed us to start the commissioning process for the power plant. We then completed some of the log stores and started receiving wood on the 3rd January 2018. The remainder of the log stores were completed, as well as the infrastructure such as roads and weighbridges that we needed to regularly bring logs on to the site. Once all the construction was finished we just needed to wait for the commissioning process to be completed and we were ready to start operating the power plant.

Project Timeline – Indicative project timeline for information purposes only

Once the construction was completed the next step was to commission the plant, which involved extensive testing of every part to ensure it was in tip top shape and all the numerous safety features were working perfectly. Commissioning took place in two phases, cold and then hot commissioning. Cold commissioning began at the end of 2017; the internal tubes were cleaned to remove any dirt, by flushing them through with warm acid. The boiler was then started up with oil rather than wood for the steam blowing tests.

This process cleans the internal surfaces of the boiler and pipework and took place over a month. The final pressure tests took place mid-February and early March before we then filled the boiler with water ready to begin generating heat and power.

Where was the plant made?

Our power plant is made from many different parts which have to be sourced from companies who specialise in the manufacture of such state of the art equipment. After a lengthy procurement exercise involving companies all over the world, the vast majority of the project will be manufactured and built by EU based companies. Companies based in the United Kingdom have secured a fair number of contracts, here’s just a few examples of those who are completing the civil works for us:

• Sword Construction from Brigg

• NB Construction from King’s Lynn

• RoofDec from Rotherham

• Caunton Engineering from Nottingham

Altogether, these businesses have employed many people during the construction programme, supporting British companies and their local teams. This goes to show that even though this is a global project sourcing from where the best equipment and the best skills can be found, buying British is still the natural choice for a significant proportion of the project and local companies are a significant part of the story.

See how we built our power plant

A high speed view from our time lapse cameras, during the main construction phase of the project.

Health and Safety

At Kent renewable biomass CHP plant we and our contractors embrace the responsibility of creating a safe working environment. All our Contractor’s lead managers have signed the Kent Safety Pledge:

“This is our project and we believe that each person working on it deserves to come home from work every evening unharmed and together we share the commitment to make that happen by maintaining a safe site and looking out for each other’s safety”.

We work closely with specialist Health and Safety companies and throughout this process we will continue to work closely with the Health and Safety Executive to make sure our project and all our team achieve the highest possible Health and Safety standards. For more information please take a look at www.hse.gov.uk/eet/ which provides a brief overview of HSE’s regulatory approach and the challenges faced by renewable energy industries.

Planning and Consents

The final elements of the planning permissions were granted by Dover District Council in mid 2016 and the £150m required to build the plant was approved by our investors Copenhagen Infrastructure II K/S, a Danish infrastructure fund, and BWSC A/S, the Danish power plant construction company in August of the same year, allowing the project to start.

Planning ref: 13/00701

Date: 18/08/2013

Erection of a biomass combined heat and power plant with fuel storage and associated works at North East side of Discovery Park & Access, Ramsgate Road, Sandwich, CT13 9ND.

Planning ref: 14/00091

Date: 14/05/2014

The use of land for additional log storage processing area and wood chip store in association with biomass combined heat plant at Discovery Park, Ramsgate Road, Sandwich, CT13 9ND

Planning ref: 15/01205

Date: 15/06/2016

Variation of Conditions 2, 6, 7, 9, 10, 11, 12, 13 and 20 of planning permission DOV/13/00701 to allow amendments to documents and plans for the erection of a biomass combined heat and power plant with fuel storage and associated works (application under Section 73) – Site North East side of Discovery Park & Access, Ramsgate Road, Sandwich, CT13 9ND

Planning ref: 15/01206

Date: 15/06/2016

Variation of Conditions 2, 5, 7, 8, 9, 10, 11 and 17 of planning permission DOV/14/00091 for the use of land for additional log storage processing area and wood chip store in association with biomass combined (application under Section 73) – Discovery Park, Site North East, Ramsgate Road, Sandwich, CT13 9ND

Planning ref: 16/00803

Date: 23/08/2016

Re-positioned access and additional areas for internal roadways, weighbridges, log storage areas, car parking, an administration building, buried electrical cabling and pipe bridge to serve the Biomass combined heat and power plant and log yard approved under DOV/15/01205 and DOV/15/01206 | Discovery Park, Ramsgate Road, Sandwich, CT13 9ND